You must consider a few key factors when buying a cutting board, such as size, material, and durability. One of the most significant decisions you will have to make is the type of cutting board you want to purchase. The three main types of cutting boards are face-grain, edge-grain, and end-grain. Each type has its unique set of pros and cons, and it is essential to understand their differences before making a purchase. We will take a closer look at face-grain, edge-grain, and end-grain cutting boards and compare their durability, cost, and aesthetic.

Face-Grain Cutting Boards

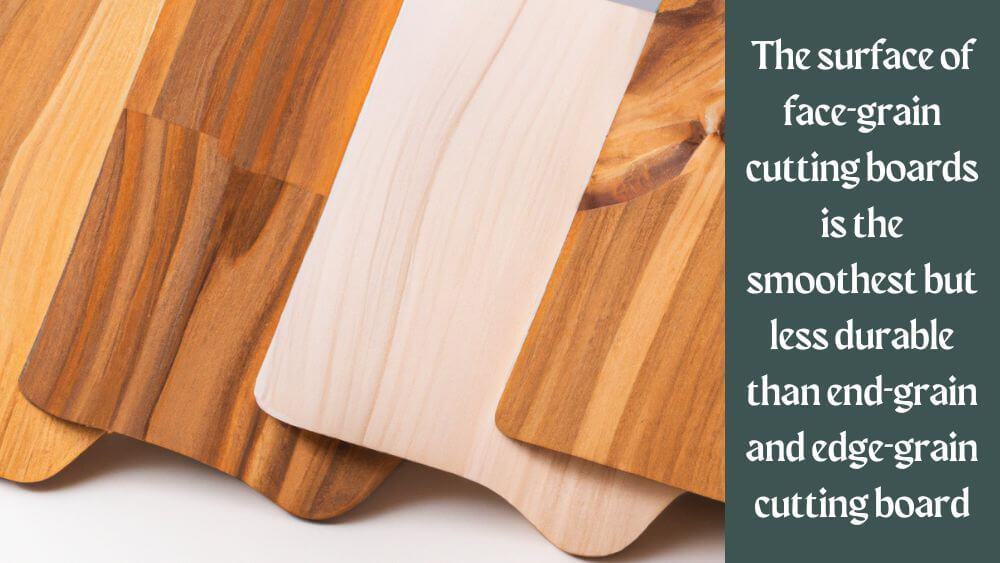

Face-grain cutting boards offer a unique look and feel that is both attractive and functional. Face-grain cutting boards are made from the face of the wood. These boards are made from planks of wood. You can cut to the desired size and thickness. Face-grain cutting boards are used to cut and chop various ingredients.

Face-grain cutting board is the most common and affordable. They are also the easiest to find in most stores. The surface of a face-grain cutting board is smooth and even, making it easy to chop and slice on. However, they are less durable than edge-grain or end-grain cutting boards. They are also more prone to warping and cracking over time.

Features of Face-Grain Cutting Boards

- Made from the face of the wood

- The most common and affordable type of cutting board

- Smooth and even surface

- Easy to chop and slice on

- Not as durable as edge-grain or end-grain cutting boards

- Prone to warping and cracking over time

- Available in a wide variety of wood types

Edge-Grain Cutting Boards

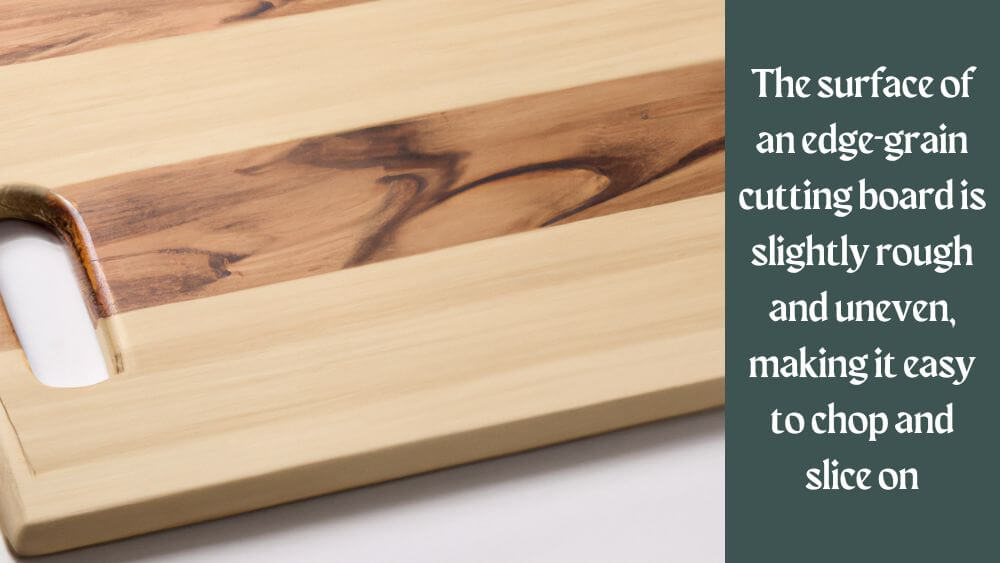

Edge-grain cutting boards are a type of cutting board made from a piece of wood’s edge (or long side). They are constructed by gluing together several wood planks, so the bites face up. This creates a linear pattern on the board’s surface that differs from that found on end-grain or face-grain cutting boards.

Edge-grain cutting boards are considered less durable than end-grain cutting boards, as the edge-grain fibers of the wood are less strong than the end-grain fibers. However, they are still considered a durable option and can last a long time with proper care and maintenance. The surface of an edge-grain cutting board is slightly rough and uneven, making it easy to chop and slice on. However, they are also more prone to warping and cracking over time.

Features of Edge-Grain Cutting Boards

- Made from the edges of the wood

- More durable than face-grain cutting boards

- Slightly rough and uneven surface

- Easy to chop and slice on

- More expensive than face-grain cutting boards

- Less prone to warping and cracking over time compared to face-grain cutting boards

- Available in a wide variety of wood types

End-Grain Cutting Boards

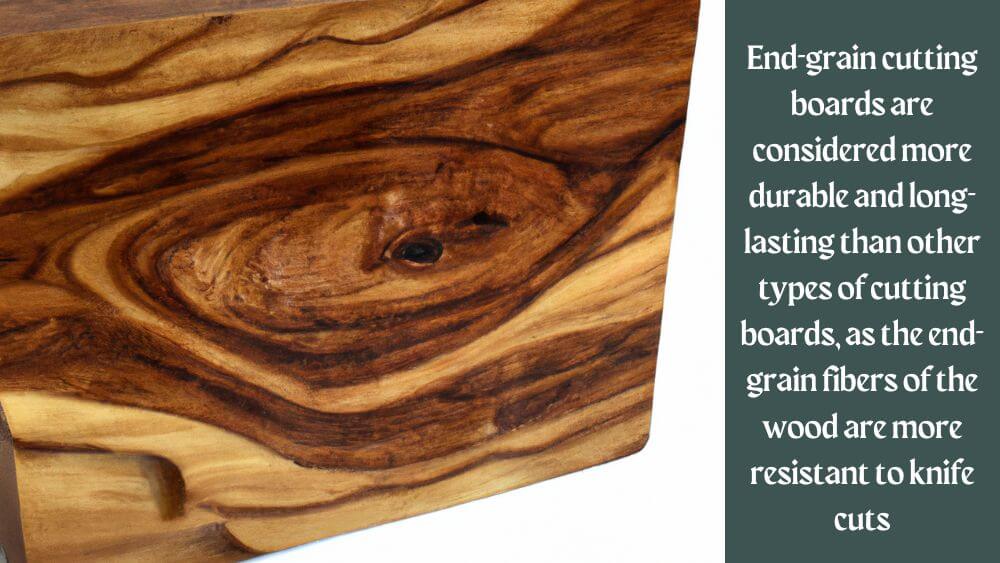

End-grain cutting boards are a type of cutting board made from the end of a piece of wood, as opposed to the side or face of the wood. They are constructed by gluing together small blocks of wood so that the end grain faces up. This creates a unique texture and pattern on the board’s surface that is not found in other cutting boards.

End-grain cutting boards are considered more durable and long-lasting than other types of cutting boards, as the end-grain fibers of the wood are more resistant to knife cuts. They are also considered more gentle on knives, as the end grain fibers compress and spring back rather than chip or dull the blade.

End-grain cutting boards are also known for their aesthetic appeal due to their unique natural patterns, colors, and textures. Aside from being eco-friendly, they also reduce waste by reusing small pieces of wood.

Features of End-Grain Cutting Boards

- Made from the end of the wood

- The most durable of the three types of cutting boards

- Rough and uneven surface

- Easy to chop and slice on

- Most expensive of the three types of cutting boards

- Least prone to warping and cracking over time

- Available in a wide variety of wood types

- Often used by professional chefs and butchers due to its durability and self-healing properties.

Comparison Between Face-Grain, Edge-Grain, and End-Grain Cutting Boards

Regarding durability, end-grain cutting boards are the most durable, followed by edge-grain cutting boards and face-grain cutting boards. In terms of cost, face-grain cutting boards are the most affordable, followed by edge-grain and end-grain cutting boards.

All three types of cutting boards have a unique look and feel. Face-grain cutting boards have a smooth and even surface, edge-grain cutting boards have a slightly rough and uneven texture, and end-grain cutting boards have a rough and uneven surface. Face-grain cutting boards are often used for kitchen islands with built-in cutting boards.

-

Durability

End-grain cutting boards are considered the most durable of the three types, followed by edge-grain and face-grain cutting boards.

-

Cost

Face-grain cutting boards are typically the most affordable of the three types, followed by edge-grain and end-grain.

-

Surface

The surface of a face-grain cutting board is smooth and even. The surface of an edge-grain cutting board is slightly rough and uneven, and the surface of an end-grain cutting board is rough and uneven.

-

Warping and Cracking

End-grain cutting boards are the least prone to warping and cracking over time, followed by edge-grain and face-grain cutting boards.

-

Aesthetics

Each type of cutting board has its unique look and feel. Face-grain cutting boards have a smooth and even surface, edge-grain cutting boards have a slightly rough and uneven texture, and end-grain cutting boards have a rough and uneven surface.

Thickness of Face-Grain, Edge-Grain, and End-Grain Cutting Boards

The thickness of a cutting board can vary, but face-grain cutting boards are generally thicker than edge-grain and end-grain cutting boards. Face-grain cutting boards are typically 1-1.5 inches thick, edge-grain cutting boards are usually about 3/4 of an inch thick, and end-grain cutting boards are around 1 inch thick. The thickness of a cutting board can affect its durability and stability, with thicker boards generally being more durable and stable than thinner ones. However, it’s important to keep in mind that the type of wood used, the quality of the craftsmanship, and the care and maintenance of the cutting board will also affect its durability and lifespan.

Pros and Cons of Face-grain, Edge-grain, and End-grain Cutting Boards

- The pros of face-grain cutting boards are that they are affordable and have a smooth and even surface. The cons are that they are less durable than edge-grain or end-grain cutting boards and are more prone to warping and cracking over time.

- The pros of edge-grain cutting boards are that they are more durable than face-grain cutting boards and have a slightly rough and uneven surface. The cons are that they are more expensive than face-grain cutting boards and prone to warping and cracking over time.

- The pros of end-grain cutting boards are that they are the most durable of the three types and have a rough and uneven surface. The cons are that they are the most expensive of the three types.

Maintenance Tips for Cutting Boards

Cutting boards can become dull and stained over time if not properly maintained. To ensure the longevity of your cutting board, there are a few maintenance tips to keep in mind.

- Do not soak the board in water for an extended period. This can cause the wood to swell, resulting in warping and cracking.

- Clean your cutting board after each use. Use warm water and mild detergent to remove any food particles and bacteria.

- Dry your cutting board thoroughly after cleaning. Moisture can cause the board to warp or crack over time.

- Use a food-safe mineral oil or butcher block oil to keep the wood hydrated and prevent cracking.

- Avoid harsh chemicals or abrasive scrubbers on your cutting board, as they can damage the surface.

- Rotate your cutting board often to ensure even wear and prevent deep cuts from forming in one spot.

- Periodically apply mineral oil or wood conditioner to the board. This will help keep the board from drying out and prevent cracking and other damage.

By following these tips, you can ensure that your cutting board will last for many years and continue to be a valuable tool in your kitchen.

Frequently Asked Questions

Which type of cutting board is the most durable?

End-grain cutting boards are considered the most durable of the three types, followed by edge-grain and face-grain cutting boards.

Which type of cutting board is the most affordable?

Face-grain cutting boards are typically the most affordable of the three types, followed by edge-grain and end-grain cutting boards.

How does the surface of each type of cutting board compare?

The surface of a face-grain cutting board is smooth and even, the feeling of an edge-grain cutting board is slightly rough and uneven, and the character of an end-grain cutting board is rough and uneven. If you want to get the smoothest cutting boards, then consider high-density polyethylene foldable cutting boards.

Are end-grain cutting boards more resistant to warping and cracking?

Yes, end-grain cutting boards are less prone to warping and cracking over time compared to face-grain and edge-grain cutting boards.

What are the differences in terms of aesthetics between the three types of cutting boards?

Each type of cutting board has its unique look and feel. Face-grain cutting boards have a smooth and even surface, edge-grain cutting boards have a slightly rough and uneven texture, and end-grain cutting boards have a rough and uneven surface.

Will a face-grain cutting board last as long as an end-grain cutting board?

No, face-grain cutting boards are not as durable as end-grain cutting boards. They are more prone to warping and cracking over time.

Are edge-grain cutting boards more expensive than face-grain cutting boards?

Yes, edge-grain cutting boards are more expensive than face-grain cutting boards.

Are end-grain cutting boards the best choice for professional chefs and butchers?

Yes, professional chefs and butchers often use end-grain cutting boards due to their durability and self-healing properties.

Can I find all three types of cutting boards in various wood types?

Yes, all three types of cutting boards (face-grain, edge-grain, and end-grain) are available in a wide variety of wood types, such as Maple, Walnut, Cherry, Oak, and more.

Can I use all three types of cutting boards for different types of food?

Yes, all three types of cutting boards can be used for different types of food, but it’s worth noting that end-grain cutting boards are often preferred for meats as they have self-healing properties. Face-grain and edge-grain cutting boards are great for fruits, vegetables and other food items.

Conclusion

When purchasing a cutting board, it is essential to understand the differences between face-grain, edge-grain, and end-grain cutting boards. Face-grain cutting boards are the most affordable and the easiest to find in most stores, but they are less durable than edge-grain or end-grain cutting boards.

Edge-grain cutting boards are more durable than face-grain cutting boards but are also more expensive. End-grain cutting boards are the most durable of the three types but are also the most costly. If you are looking for a cutting board that is both durable and affordable, an edge-grain cutting board might be the best choice for you. If you are looking for a cutting board that is both durable and has a unique aesthetic, an end-grain cutting board might be the best choice for you.

As the chief content writer, Hassan Al Sarker works as a professional kitchen-based content creator at Kitchen Liker.

In addition to reviewing the content published on Kitchen Liker, he ensures that it is accurate, relevant, and helpful. As a result, all the reviews and information published at Kitchen Liker are neutral and userfriendly.

Hassan Al Sarker has a bachelor’s degree in Hotel and Tourism Management From the Newyork University. Before joining Kitchen Liker, he was a contributor at Kitchen Club, United States.